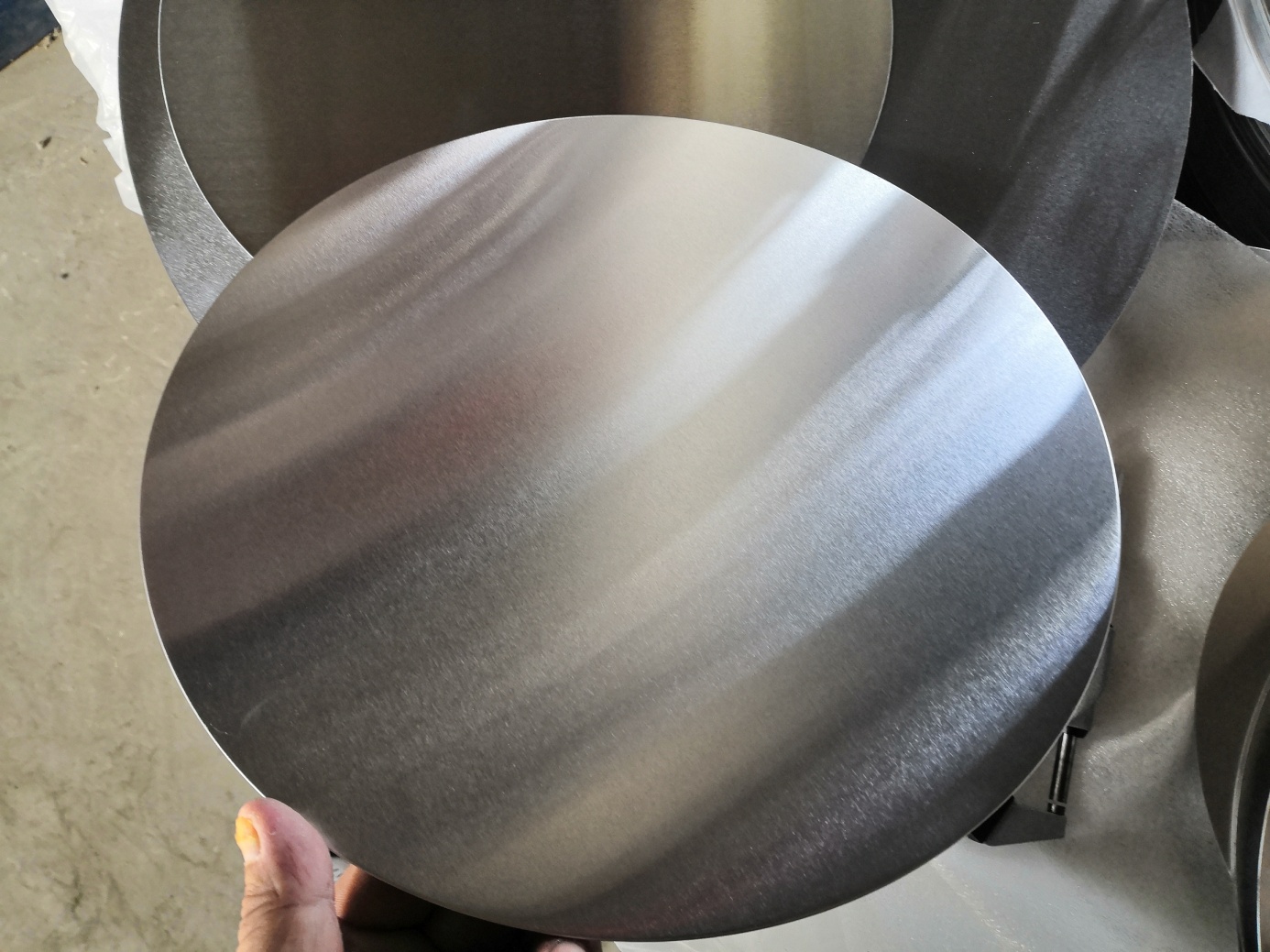

Unveiling 1060 Aluminum Circle in Burkina Faso: Characteristics, Advantages and Applications

1. Panimula

In the industrial development of Burkina Faso, 1060 Aluminum Circle has become an indispensable basic material in local construction, electronics, daily necessities manufacturing and other fields, relying on its core advantages of high purity, easy processability and strong adaptability. As a representative product of the 1XXX series pure aluminum, 1060 Aluminum Circle not only meets Burkina Faso’s demand for cost-effective industrial materials, but also satisfies its diverse application scenarios in infrastructure construction and daily necessities production. This article will comprehensively analyze it from six dimensions: komposisyon ng kemikal, core parameters, Mga katangian ng mekanikal, product characteristics, outstanding advantages and local applications, providing accurate product references for industry practitioners and purchasers in Burkina Faso.

2. Chemical Composition of 1060 Aluminum Circle

2.1 Core Element Content

Ang komposisyon ng kemikal ng it strictly complies with the GB/T 3190 “Chemical Composition of Aluminum and Aluminum Alloys” standard, with high-purity aluminum as the base and extremely low content of impurity elements. The specific element proportions are shown in the table below:

| Elemento | Content Range | Function Description |

| aluminyo (Sinabi ni Al) | ≥99.60% | Core matrix element, determining the high purity and basic performance of it |

| Silicon (At) | ≤0.25% | Controlled at a low content to avoid the formation of brittle compounds and ensure the processability of it |

| bakal (Fe) | ≤0.35% | Trace addition can improve the hot-rolling process stability of it without affecting ductility |

| tanso (Cu) | ≤0.05% | Strictly limited to prevent reducing the corrosion resistance of it |

| Magnesium (Mg) | ≤0.05% | Low content avoids changing the mechanical property balance of it |

| Sink (Zn) | ≤0.05% | Reduces the interference of impurities on the electrical and thermal conductivity of it |

| Manganese (Mn) | ≤0.03% | Controlled in trace amounts to ensure the dimensional stability of it after forming |

| Titanium (Ng) | ≤0.03% | Assists in grain refinement and improves the mechanical uniformity of it |

| Vanadium (V) | ≤0.05% | Impurity element, total content controlled to ensure the purity of it |

2.2 Impact of Elements on Performance

- aluminyo (Sinabi ni Al): The high aluminum content of ≥99.60% is the core foundation for it to have excellent corrosion resistance and thermal conductivity. Kasabay nito, it provides a guarantee for its characteristics of “easy processability and no harmful substance release”, making it suitable for food contact and medical auxiliary parts scenarios in Burkina Faso.

- Impurity Elements (At, Fe, atbp.): The strictly limited impurity content (total impurities ≤0.15%) can prevent it from cracking and deformation during stamping and stretching processes, and at the same time avoid performance degradation due to impurity precipitation during long-term use, which meets Burkina Faso’s demand for product durability.

3. Core Parameters of 1060 Aluminum Circle

3.1 Basic Specification Parameters

In response to the processing needs of different industries in Burkina Faso, the specifications of 1060 Aluminum Circle can be flexibly customized. The common basic parameters are shown in the table below:

| Parameter Category | Range/Standard | Applicable Scenarios |

| kapal | 0.3mm~12mm | 0.3mm~2mm for daily necessities (such as kitchenware, decorative parts); 3mm~12mm for building structural parts, all designed based on the characteristics of 1060 Aluminum Circle |

| diameter | 50mm~2400mm | 50mm~300mm for small electronic accessories; 300mm~2400mm for architectural decoration and large container bases, meeting the application needs of 1060 Aluminum Circle of different sizes |

| Thickness Tolerance | ±0.05mm | Ensures the dimensional consistency of 1060 Aluminum Circle during batch processing and reduces material waste |

| Diameter Tolerance | ±0.3mm | Adapts to the stamping needs of automated equipment and improves the production efficiency of 1060 Aluminum Circle |

| Surface Roughness | Ra≤1.6μm (regular); Ra≤0.8μm (mirror) | Regular roughness is suitable for 1060 Aluminum Circle structural parts; mirror finish is suitable for 1060 Aluminum Circle decorative products |

3.2 Compliance with Implementation Standards

The production and testing of 1060 Aluminum Circle strictly comply with a number of international and industry standards to ensure application compliance in Burkina Faso, kasama ang:

- Chinese Standards: GB/T 3880.2 “Aluminum and Aluminum Alloy Plates and Strips for General Industrial Use – Part 2: Mechanical Properties”, GB/T 3190 “Chemical Composition of Aluminum and Aluminum Alloys”;

- International Standard: ASTM B209 “Standard Specification for Aluminum and Aluminum Alloy Plates and Strips”;

- Food Contact Standard: GB 4806.1 “National Food Safety Standard – Metal Materials and Products for Food Contact” (applicable to 1060 Aluminum Circlein kitchenware and food packaging scenarios in Burkina Faso).

4. Mechanical Properties of 1060 Aluminum Circle

The mechanical properties of 1060 Aluminum Circle vary with processing states (such as annealed state, cold-worked hardened state), which can adapt to scenarios with different strength requirements in Burkina Faso. The specific performance parameters are shown in the table below:

| Mechanical Property Index | Temper O (Fully Annealed) | Temper H12 (Light Cold Work Hardened) | Temper H14 (Medium Cold Work Hardened) | Test Standard |

| Lakas ng makunat (σb) | ≥95MPa | 110~130MPa | 120~140MPa | GB/T 228.1 (Applicable to 1060 Aluminum Circle) |

| Lakas ng Yield (σ0.2) | ≥45MPa | ≥70MPa | ≥85MPa | GB/T 228.1 (Applicable to 1060 Aluminum Circle) |

| Pagpahaba (δ5) | ≥28% | 15%~20% | 10%~15% | GB/T 228.1 (Applicable to 1060 Aluminum Circle) |

| Brinell Hardness (HB) | ≤15HB | 18~22HB | 22~25HB | GB/T 231.1 (Applicable to 1060 Aluminum Circle) |

Performance Interpretation

- Temper O (Fully Annealed): 1060 Aluminum Circle in Temper O has the highest ductility (elongation ≥28%), which is suitable for deep drawing processing in the daily necessities industry of Burkina Faso, such as kitchenware pot bodies and decorative curved accessories;

- Temper H14 (Medium Cold Work Hardened): The tensile strength of 1060 Aluminum Circle is increased to 120~140MPa, which can meet the strength requirements for structural parts in the local construction field, such as lightweight curtain wall decorative parts and door and window frame accessories;

- Hardness Control: The characteristic of Brinell hardness ≤25HB allows 1060 Aluminum Circle to be processed with ordinary cutting and drilling equipment, reducing the equipment investment cost of small and medium-sized enterprises in Burkina Faso.

5. Core Characteristics of 1060 Aluminum Circle

5.1 High Purity Advantage

1060 Aluminum Circle has an aluminum content of ≥99.60%, which belongs to the category of industrial pure aluminum. It has no risk of heavy metal (lead, cadmium, mercury, atbp.) precipitation. It not only meets the safety requirements for food contact products in Burkina Faso, but also can reduce corrosion in humid environments and extend the service life of products made from 1060 Aluminum Circle.

5.2 Excellent Formability

Whether it is stamping, deep drawing, bending or welding, it can maintain stable processing performance. In Temper O, it can be easily formed into complex curved surfaces (such as kitchenware handles and electronic equipment casings) without cracks or deformation after processing, which is suitable for the small-batch and multi-category production needs of 1060 Aluminum Circle in Burkina Faso.

5.3 Strong Corrosion Resistance

A dense aluminum oxide (Al₂O₃) film is naturally formed on the surface of it. This film can block moisture, air and common corrosive media. Even in the humid environment of Burkina Faso’s rainy season, it can prevent from rusting and oxidation, making it particularly suitable for the application of in outdoor architectural decoration, rainwater pipe accessories and other scenarios.

5.4 Efficient Electrical and Thermal Conductivity

The thermal conductivity of it is ≥200W/(m·K), and the electrical conductivity is ≥55%IACS, which is much higher than that of steel, iron and other metal materials. In the electronics industry of Burkina Faso, it can be used to manufacture small heat sinks and wire and cable shielding parts; in the daily necessities field, it can be used to make kitchenware with fast heat conduction, improving the user experience of products made from it.

6. Outstanding Advantages of 1060 Aluminum Circle

6.1 Cost-Effectiveness

Compared with alloy aluminum circles such as 3003 at 5052, it has a simpler production process and lower raw material costs. Kasabay nito, the scrap rate during processing is ≤3%, which can effectively reduce the cost of purchasing it for enterprises in Burkina Faso, and is especially suitable for small and medium-sized manufacturing enterprises with limited budgets.

6.2 Processing Diversity

1060 Aluminum Circle is compatible with a variety of post-processing technologies, tulad ng anodizing (which can be dyed into silver, gold, black and other colors to meet decorative needs), painting, laser marking, atbp. It can meet the personalized needs of it in architectural decoration and branded daily necessities production in Burkina Faso.

6.3 Long-Term Durability

Combining high purity and strong corrosion resistance, the service life of products made from 1060 Aluminum Circle can reach 5~10 years (such as outdoor architectural decorative parts and household kitchenware), which reduces the frequency of replacing products made from 1060 Aluminum Circle for users in Burkina Faso and lowers long-term use costs.

6.4 Environmental Sustainability

Aluminum is a 100% recyclable metal. it can retain more than 95% of its original performance after recycling, which is in line with the trend of promoting green industrial development in Burkina Faso and helps the local area achieve the goal of “resource recycling of it“.

Why choose us?

Eco-alum (Eco-Alum Aluminum Co., Ltd.) has a wide range of business scope, covering the sales of metal materials and products, hardware product research and development and sales, electronic products and communication equipment sales, and also involves cutting-edge businesses such as information technology and new material technology research and development, providing customers with comprehensive aluminum product-related services.

7. Application Scenarios of 1060 Aluminum Circle in Burkina Faso

7.1 Industriya ng konstruksyon

- Outdoor Decoration: After stamping and anodizing, 1060 Aluminum Circle can be made into building curtain wall decorative parts and roof vent covers. Its corrosion resistance can resist the humidity and sand in Burkina Faso’s rainy season;

- Door and Window Accessories: it with a thickness of 3mm~5mm can be processed into door and window handle bases and hinge accessories. With moderate strength (tensile strength of 120~140MPa in Temper H14), it ensures stable use;

- Infrastructure: In the auxiliary structures of small bridges and rainwater pipes, it can be used as the base material for connecting parts, taking into account light weight and weather resistance.

7.2 Electronics and Electrical Industry

- Small Heat Sinks: Using the high thermal conductivity of it, it can be made into heat sinks for mobile phone chargers and small LED lamps, solving the heat dissipation problem of electronic equipment in the high-temperature environment of Burkina Faso;

- Electrical Casing Accessories: it in Temper O can be stamped into casing parts of small household appliances (such as electric fans and electric irons). Its easy processability can meet the diverse casing design needs.

7.3 Daily Necessities and Decoration Industry

- Kitchenware Manufacturing: This is the most extensive application scenario of it in Burkina Faso. it in Temper O with a thickness of 0.8mm~2mm can be deep drawn into the bodies of woks, milk pots and soup pots. It has uniform heat conduction and no harmful substances released, meeting the local family’s demand for safe kitchenware;

- Decorative Products: it with mirror finish can be made into billboard bases and indoor wall decorative parts. Its bright surface can improve the aesthetics of products, adapting to the decoration needs of shops and hotels;

- Daily Necessities Accessories: it with a thickness of 0.3mm~1mm can be processed into thermos cup lids and cosmetic jar bottoms. With its lightweight characteristic, it improves the portability of products.

8. Konklusyon

Through the comprehensive analysis of chemical composition, parameters, performance and characteristics, it can be seen that it takes “high purity, easy processability and high cost-effectiveness” as its core competitiveness, and perfectly adapts to the actual needs of industrial development in Burkina Faso. In the construction field, it can withstand the local climate test; in the electronics field, it can meet the demand for efficient heat conduction; in the daily necessities field, it can balance safety and cost – becoming an important material for promoting infrastructure construction and upgrading of daily necessities in Burkina Faso.

In the future, with the growth of Burkina Faso’s demand for green industry and lightweight materials, the application scenarios of it will be further expanded, such as new energy equipment accessories and environmentally friendly packaging materials. Its characteristics of “Recyclable, low energy consumption and strong adaptability” will also help Burkina Faso realize the sustainable development of industry and inject more vitality into local economic growth.